Redefining Construction: Prototype TOVA by Posgrado 3D Printing Architecture IAAC

In response to the pressing need for more sustainable design and construction practices, the Prototype TOVA project emerged as a pioneering endeavor to integrate additive manufacturing (3D printing) with traditional clay building techniques. Recognizing the environmental impact of current production and consumption models, the project aimed to harness the inherent qualities of both technologies to foster more sustainable construction practices.

Innovative Approach

TOVA stands as the first clay prototype utilizing additive manufacturing in Ibero-America. Developed by a team of students and professionals from the 3D Printing Architecture postgraduate program at the Institute for Advanced Architecture of Catalonia (IAAC), the project was situated in Collserola Park in Barcelona, Spain, near Valldaura Labs. This location facilitated the use of locally sourced materials, with clay and water obtained within a 500m radius of the construction site, emphasizing sustainability and contextual integration.

Performative Design Strategies

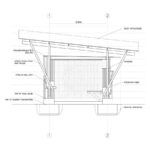

The project employed performative design strategies to address various aspects such as light, air flow, thermal conductivity, and structural integrity. These strategies were conceptualized during a two-week design charette, allowing students to synthesize research findings and develop components of the prototype, including wall structures, roof systems, and interior features.

Integration of 3D Printing Technology

With a built area of 9m2, TOVA exemplifies the potential of 3D printing technology in construction. The project’s schematic distribution and printing logistics were carefully planned to enable production by a team of 18 students within a two-month timeframe. Structural considerations, including roof beam systems and clay wall structures, were meticulously designed to ensure habitability, weather resistance, and climatic adaptability.

Collaborative Learning Experience

The project fostered a collaborative learning environment, with students participating in workshops and design discussions to refine their understanding of 3D printing technology and sustainable construction practices. The collective effort culminated in the construction of a 1:1 scale housing prototype, showcasing the feasibility of utilizing clay and wood in additive manufacturing processes.

Conclusion

Prototype TOVA represents a significant step towards redefining construction practices by combining innovative technologies with traditional building materials. The project’s success underscores the potential of additive manufacturing in creating sustainable, contextually integrated architectural solutions. Developed in collaboration with WASP and financed by BBSR/Zunkunfbau, TOVA serves as a testament to the possibilities of interdisciplinary collaboration in advancing sustainable design and construction.